VH-Z Series Vertical Filter Industrial Dust Collector Air Purification System

Product Description

VH-Z Series is a central dust collection system with large air volume. This system is equipped with a pulse jet self-cleaning filter mechanism and vertical installation of filter cartridges which increases the filtration efficiency by several percent.

Applications

Suitable for capacitance spray operations, tin packaging operations, CCL operations, spraying production line operations, ceramic raw embryo processing, polishing workshop, welding smoke purification and other multi-site centralized dust conditions.

Features

1. The filter material is polyester with PTFE coated, which can filter 99.9% dust at 0.3 microns.

2. Pulse jet cleaning method for the filter makes machine to work continuously. User can set the pulse frequency depending upon the requirements.

3. Vertical installation would protect the filter from dust accumulation, which would ultimately increase the filter life, reduce gasket leaks, and result in better pulse cleaning.

4. Real-time monitoring of machine pressure changes can quickly detect whether the filter needs to be cleaned.

3. Vertical installation would protect the filter from dust accumulation, which would ultimately increase the filter life, reduce gasket leaks, and result in better pulse cleaning.

4. Real-time monitoring of machine pressure changes can quickly detect whether the filter needs to be cleaned.

Structure Diagram

Technical Parameters

| Model | VH-Z-8500 | VH-Z-16000 | VH-Z-19000 | VH-Z-21000 | VH-Z-23000 | VH-Z-30000 |

| Voltage(V/Hz) | 380 / 50 | |||||

| Air flow (m³/h) /(CFM) | 5710~10600 / 3360~6240 | 10600~21200 / 6240~12470 | 13200~26300 / 7765~15470 | 17500~22450 / 10300~13200 | 19650~25250 / 11560~14850 | 28100~36450 / 16530~21450 |

| Power(kW) / (HP) | Calculate the total pressure/static pressure according to the total resistance of the system, and then select the appropriate fan power | |||||

| Filter area(m²)/ ( sq.ft ) | 84/904 | 170/1830 | 204/2196 | 204/2196 | 306/3294 | 360/3875 |

| Filter efficiency | 99% | |||||

| Capacity of the dust container(L)/ (gal) | 70 /18.5 | 50×2 /13.2×2 | 50×2 /13.2×2 | 50×2 /13.2×2 | 50×2 /13.2×2 | 50×3 /13.2×2 |

| Noise dB (A) | 82±2 | 83±2 | 85±2 | 85±2 | 88±2 | 90±2 |

| Filter cleaning method | pulse jet cleaning+holder on dust collecting box | |||||

| Dia. air inlet (mm) / (in) | Ø350 / 14 | Ø500 / 20 | Ø550 / 22 | Ø550 / 22 | Ø600 / 24 | Ø650 / 26 |

| Dimension (Excluding the Blower)[L*W*H] (mm) / (in) | 1450*1134*1963/ 57.1*44.6*77.2 | 1840*1350*2075/ 72.4*53.1*81.7 | 2000*1350*2075/ 78.7*53.1*81.7 | 2000*1350*2075/ 78.7*53.1*81.7 | 2500*1500*2200/ 98.4*59.1*86.7 | 2500*1500*2400/ 98.4*59.1*94.5 |

| Mobility | Fixed holder | |||||

| * The air flow and Negative pressure is adjustable according to the actual condition,and then choose the bigger or more suitable power machine. | ||||||

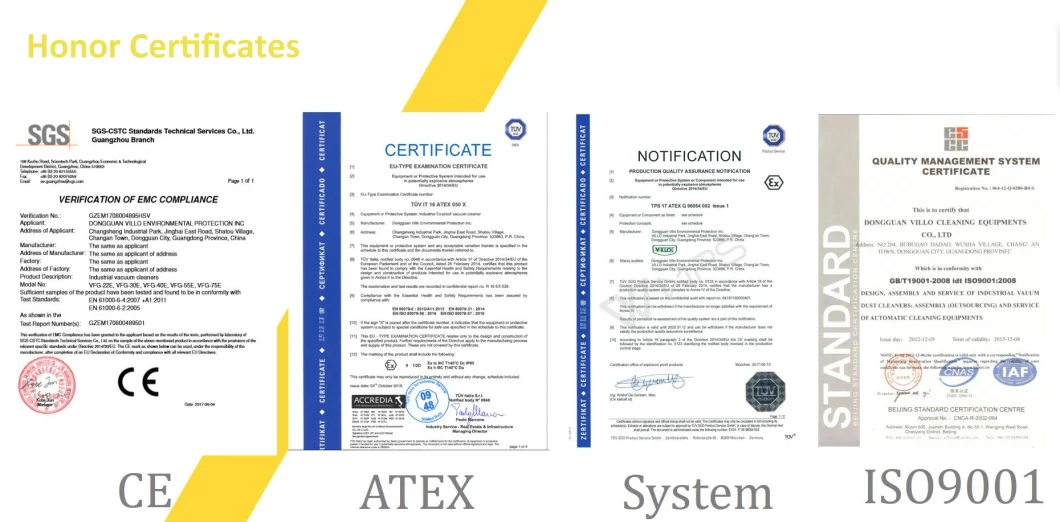

Certifications

Our Company